2020-10-21 13:05:02

With the continuous improvement of my country's manufacturing level, the multi-machine efficient and collaborative working method will surely replace heavy and complex manual operations, and the work of smart machines will also replace the backward production work methods of traditional industries and become the promotion of industrial development and economic construction. Important motivation. As a traditional and indispensable industry, geological drill pipe survey needs to comply with the development of society and complete industrial upgrading and transformation of operation methods.

In traditional geological drilling operations, the drilling and unscrewing of the drill pipe requires manual handling, and the drilling rig completes the entire operation. Because some ultra-deep drilling processes require a large amount of drill pipe and the unit drill pipe weight is heavier ( A single drill rod can reach 100 kilograms), which has produced tremendous physical work for the operators and seriously affected the efficiency and quality of the drilling rig. Moreover, drilling scenes of various terrains, including mountains, rainforests and grasslands, put forward strict requirements on equipment and personnel, and the equipment is needed to facilitate transportation, assembly and operation.

● Project construction goals

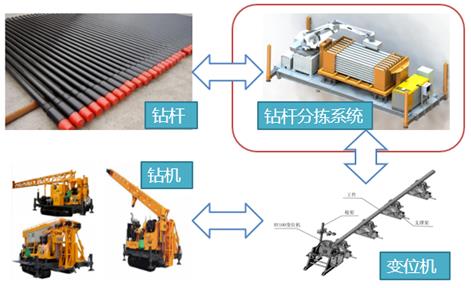

Develop and manufacture the drill pipe sorting system, cooperate with the positioner to complete the loading and receiving of the drill rod, not only to ensure that the drill rod can be picked up from the drill rod box to the downstream positioner, but also to ensure that it is picked and placed from the positioner. Back to the drill pipe box, the specific content is as follows:

The overall system is installed on the load-bearing platform. After the load-bearing platform reaches the designated position, the overall system is leveled;

The drill rods are placed neatly in the drill rod box horizontally, and the load capacity of the drill rod box is 50;

The robot takes out the drill rods from the drill rod box one by one through the fixture and places them horizontally on the positioner or takes out the drill rods from the positioner and places them horizontally in the drill rod box;

The system can be operated by industrial wireless controller;

The positioner has a communication interface, and the system can communicate with the positioner I/O.

● Project construction content and key technology application

(1) Robot system

The vertical robot is used for sorting operations, which can meet the loading and unloading of drill pipes. Due to the limited space, the distance between the drill rod box and the robot is relatively close. In order to satisfy the drill rod within the working range of the robot, the base is used to raise the robot to make full use of part of the working space on the robot and maximize the working range of the robot.

The robot is equipped with protective clothing to adapt to the field environment when working on site.

Robot system renderings

(2) Drill pipe lifting system and drill pipe box

The drill rod box can be replaced. Each drill rod box can hold 50 drill rods, arranged in 5*10, and each column is separated by square steel, and the distance is about 50mm. The bottom of the drill rod box is a movable lifting plate to ensure that the robot only picks up and places the highest drill rods. After the top 10 rods are removed or placed one by one, the elevator lifts the plate to drive the drill rods up or down, and then the robot repeats the loading and unloading actions.

The elevator load needs to be greater than 4t, and its placement space is limited. It needs to be located below the drill pipe box. Therefore, only hydraulic elevators can be used. Because the hydraulic elevator has low accuracy, photoelectric sensors need to be used to detect the closed-loop feedback position of the top drill pipe.

(3) Load-bearing lifting platform system

When the lifting platform is raised, it can meet the requirement of 30 to 40 tons of flatbed transfer trucks to invert the whole set of equipment. The power of the hydraulic system of the lifting platform is 11kW. The 4 lifting legs and 4 translation cylinders can be separately controlled by the remote control. The bottom of the platform is equipped with an inclinometer, which can feedback the tilt angle of the platform to the display control panel, refer to the interface display angle, and remotely control the corresponding lifting cylinder leveling through the remote control.

(4) Software system

The software system provides the necessary operations of the robot and the lifting platform, including start, stop, pause, parameter call, lift movement, sensor detection, status main parameter display, alarm, etc.

● Project implementation effect

The application of robot integration technology to the complex environment in the field can provide inspiration for the geological drilling industry. The rapid disassembly and rapid integration of robots can play an important role in certain specific tasks. Not only the drill pipe is automatically sorted, but also the robot can play an important role by changing the fixture in some heavy and single tasks. In field drilling and surveying, the use of automatic drill pipe sorting system is the first in the domestic industry. The working mode that combines equipment such as drilling rigs and automatic drill pipe sorting systems for drilling and exploration scenarios has been implemented in a field simulation drilling and investigation scenario in a certain place in China, and has achieved positive results.